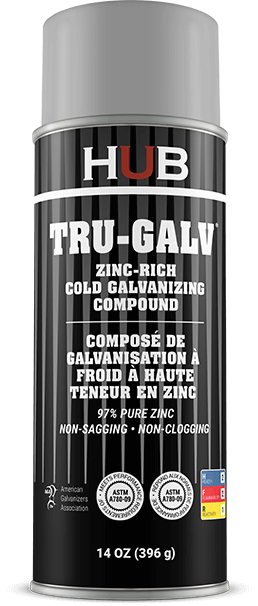

TRU-Galv® The Best Choice For Touch-Up And Repair Of Galvanized Substrates

HUB's lineup of cold galvanizing aerosols has something for everyone. If you are touching up brand-new hot-dipped work, the QWIK-DRY variant is your best choices for perfect color match. The Silver Pro and Silver both have a slightly darker color, and the Zinc-Rich delivers a classic battleship grey.

The sacrificial properties of the zinc content of the coating inhibit rusting of the steel being protected. ASTM B117 salt spray tests show TRU-Galv® coatings meet or beat the corrosion resistance of other aerosol coatings.

TRU-Galv® galvanized coatings are professional grade products used by galvanizing plants to touch up hot-dipped steel. They also are extensively used by fencing pros as well as anyone else who needs to protect bare steel from corrosion. All TRU-GALV® formulations comply with ASTM A780 specifications.

Uses / Applications: Power plants and transmission towers, fences, gutters, bridges, structural steel, wrought iron, farm equipment, damaged galvanized surfaces, highway maintenance and marine applications.